Replenishment planning is all about building a replenishment strategy that works for your business—ensuring you have the optimal volume of inventory on hand to meet customer demand while avoiding stockouts and overstock. Such a replenishment-planning strategy is crucial for the operation of a successful business.

Without replenishment planning, you’re going to be faced with supply-chain issues such as overstocks or, worse still, not enough stock. This will result in lost profits either way.

Too much stock takes up room for other items, while too little stock means you won’t be able to keep up with customer demand. These issues highlight the importance of always having up-to-date store-level information about your inventory.

Being unable to fulfil orders is also likely to damage your reputation and force customers to shop elsewhere.

So, what’s replenishment planning, and why do we need it? Let’s break it down together.

What is Replenishment Planning?

Replenishment planning is vital to inventory optimization, as it involves creating a replenishment strategy to keep your supply chain running at its optimal levels. It’s not just about reordering stock but anticipating your future stock needs as well, ensuring that you always order the optimal order quantity for your needs.

Use Cases of Replenishment Planning

Replenishment planning can include any of the following example use cases:

- Shipping materials from a supplier to a manufacturer.

- Transporting inventory from storage to packing and shipment locations.

- Ordering new inventory from suppliers to ensure stock levels are adequate and fulfillment can be reached.

- Relocating inventory from a warehouse to a retail store or pickup location.

Replenishment planning takes into account all the variables and constant changes that alter your inventory requirements. From here, you can make the best decisions to keep your supply chain active and optimized.

The Benefits of Replenishment Planning

Some of the most obvious business benefits of replenishment planning include being able to:

- Maintain optimal inventory levels at each level of your supply chain to meet customer-service targets.

- Monitor and make predictions on the performance of your inventory policies.

- Keep on top of large-scale replenishment.

- Keep customers satisfied and on board.

- Replenishment-planning process

Thankfully, with tools like Inventory Planner, replenishment planning is made easier. So, whether it’s demand replenishment planning, distribution replenishment planning, or anything else, there’s software which will automate all of this manual work for you.

The Importance of Replenishment Planning

Warehouse replenishment is an important process that requires planning. A great strategy gives you the chance to gain an advantage over competitors and keep your customer base satisfied.

If an item you’ve advertised for sale is out-of-stock, customers could move to another vendor and never return. Why would they wait weeks for you to get it back in stock if a company down the street has plenty? Worse still, if the item is popular, customers are likely to tell friends and family where they can find it, and you don’t want that to be with a competitor!

Poor replenishment planning isn’t just about not having an item in stock. You might not be able to stock it because of an earlier mistake. As a business, it’s frustrating when customers can’t get the items they want, but you’re going to be even more frustrated if you can’t physically stock the item because you’re overstocked with other items that no one is buying.

The reality of these types of situations is a decrease in profits and reputation. A good replenishment-planning strategy avoids that, taking everything into account to optimize your replenishment process and make data-informed decisions that make the most sense.

Common Inventory Issues

Some of the common inventory issues that replenishment planning can help with are:

- Widely varying customer demand patterns.

- Differing inventory policies.

- Many items and locations to manage.

- Limited diagnosis/problem-solving.

How does replenishment planning help?

A solid replenishment-planning process will let you:

- Calculate service-level-based inventory policies and thresholds.

- Integrate demand forecasting and time-phased stock replenishments.

- Perform stock policy simulation and planning.

- Leverage data-backed analytics and exception monitoring.

The Evolution of Replenishment Planning

In years gone by, replenishment was largely a manual process involving clipboards and pens, performing physical stock checks, and updating spreadsheets. But thanks to digital transformation and the emergence of AI, the replenishment-planning process has changed for the better.

Today, the best replenishment-planning solutions use automation and other tech-enabled techniques to ensure the most common inventory problems are handled efficiently in real time.

They may be standalone solutions or integrated with other solutions in an ERP.

Best Practices for Inventory Replenishment Planning

When it comes to inventory planning and replenishment, there are some best practices that you can follow to get the best out of your efforts:

Assist your suppliers

Teamwork makes the dream work, which is why you need to assist your suppliers.

Suppliers aren’t mind readers; if you’re running low on stock, you need to let them know. Thankfully, collaborative tools, often cloud-based, can now bring suppliers and buyers together for practical solutions.

For example, if you share a collaborative supply-chain management tool with your suppliers, you could automatically schedule regular deliveries of inventory when stock becomes low. But what if you don’t want the same stock this time?

You can tell your suppliers about any changes to repeat orders to prevent you from ending up overstocked with an item you no longer want in your warehouse.

Keeping communication open with your suppliers will help you avoid last-minute surprises and prevent small issues from becoming large-scale nightmares.

Some common issues caused by a lack of communication with suppliers are:

- No room for trucks to pull in if several suppliers arrive at a similar time.

- Suppliers arriving with scheduled deliveries without being told there’s been a change.

- Health and safety issues.

- Money wasted on incorrect or unnecessary inventory.

Determine practical service levels

Service levels refer to the expected probability of satisfying all inventory requirements within a particular time period.

For example, if your service-level target is 95%, this means your safety-stock levels will cover 95% of all probable order requests. In other words, you’ll be able to give your customers what they want on time, 95% of the time.

Hitting service-level targets is crucial for staying profitable and keeping customers satisfied. But how do you decide on practical service levels?

Service-level targets are usually set for each individual item. You wouldn’t simply have 1000 of every item; this is unlikely to reflect what your customers are demanding. One of the best ways to determine service levels is to use ABC inventory analysis.

At its most basic, ABC inventory analysis sets the highest service levels for the items that generate the most revenue. If an item is popular, you’ll want to prioritize its supply to keep customers happy.

More complex methods may include grouping items by demand volatility, pick frequency, or net profit. From here, you’ll be able to adjust your service levels to make them higher for items that are cheaper to have in stock and have steady demand, while a lower service level would work for expensive items that sell less.

By setting service levels and measuring them continuously, you’ll be able to make better replenishment-planning decisions with minimized risk.

Consider product life cycle

Replenishment planning is dependent on a number of factors throughout a product’s life cycle. Therefore, you’ll need to understand all the stages your inventory goes through, from distribution to the channels where items are sold.

Some obvious areas to assess in distribution include:

- Manufacturing times.

- Packing and shipping times.

- Lead times.

- Warehouse processing time.

- Customer order fulfillment.

- New order allocations.

Understanding the life cycle of your inventory at these different stages will help you make better replenishment-planning decisions.

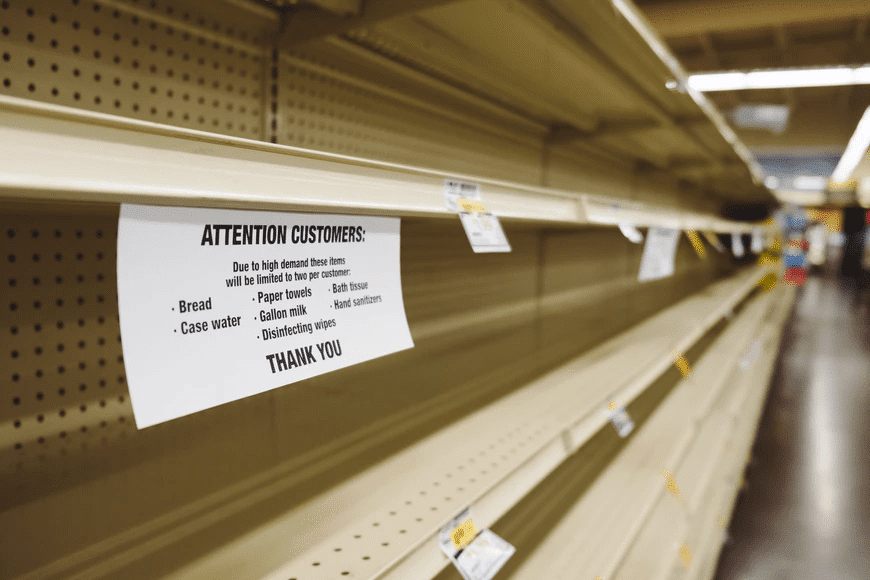

Prevent Stockouts

Put yourself in the shoes of a customer. You’ve rushed to the store in desperate need of toilet paper only to find that they have none on the shelf when you arrive. You’re going to feel annoyed and probably take your business elsewhere.

Using an inventory management system that automatically keeps a tab on stock levels will help prevent an out-of-stock situation. Data can also be analyzed in real time to spot trends that might lead to out-of-stock situations.

For example, you might still have lots of a particular item in stock. But what if this item surges in popularity? You’ll need to bring your reorder point for that item forward so that you can order more stock as soon as possible to supply the demand. This is known as demand forecasting. We’ll look at this in more detail further on.

Some common methods of preventing out-of-stock situations are to:

- Utilize buffers – If you only have five units of an item in stock, you can set a buffer that will take it off the marketplace while you order more. This will prevent out-of-stock situations.

- Utilize demand forecasting – Spot trends and analyze data to inform your replenishment process.

- Reduce human error – Under-trained staff? Overworked staff? Both could cause inventory errors. If staff have to manually input stock quantities and other data, think about switching to a scanning system; it’ll remove the possibility of human error.

- Perform regular cycle counts – Keep your inventory organized and perform regular cycle counts to reduce issues with the quantity of stock you have available.

- Implement quality control – Quality control staff can spot problems and find fast solutions.

Set up demand forecasting and consider other factors

Replenishment planning is all about acquiring new products to support anticipated needs. Demand forecasting helps predict that future need.

In the past, demand forecasting relied on the experience of the buyer to spot patterns or make educated guesses. But thanks to digital transformation, we now have software solutions with functionality that enables data-informed algorithms to accurately forecast future demand.

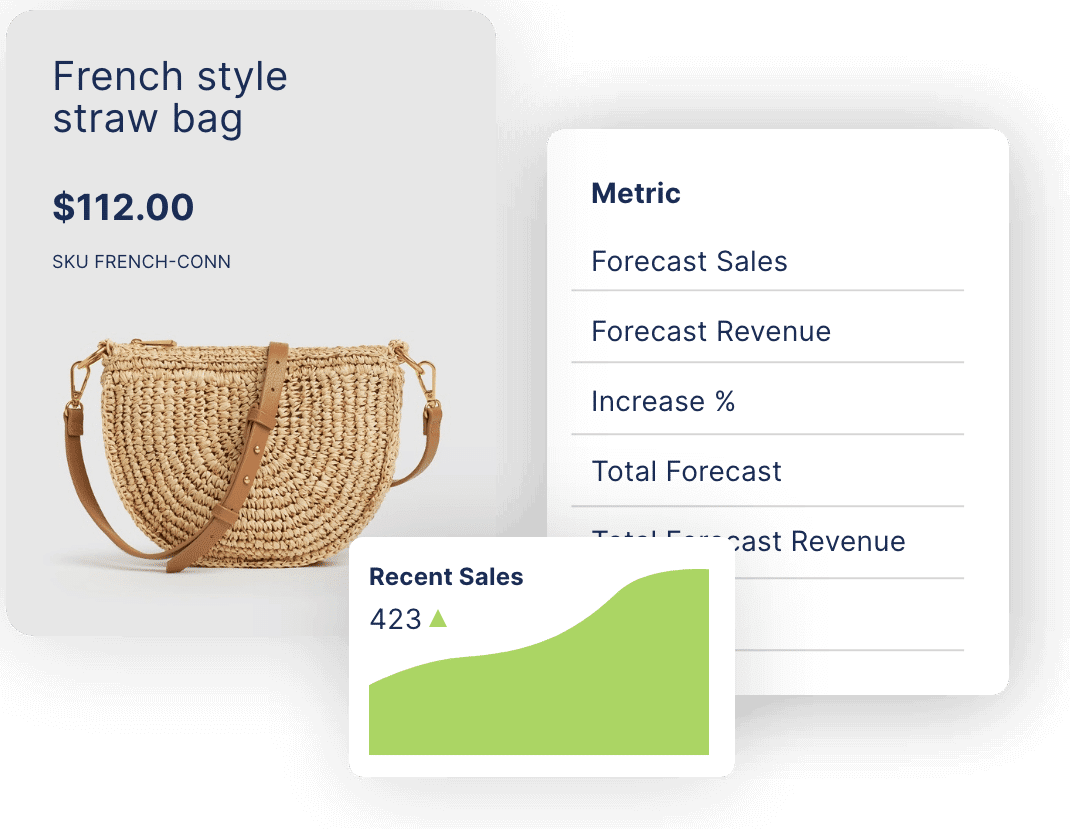

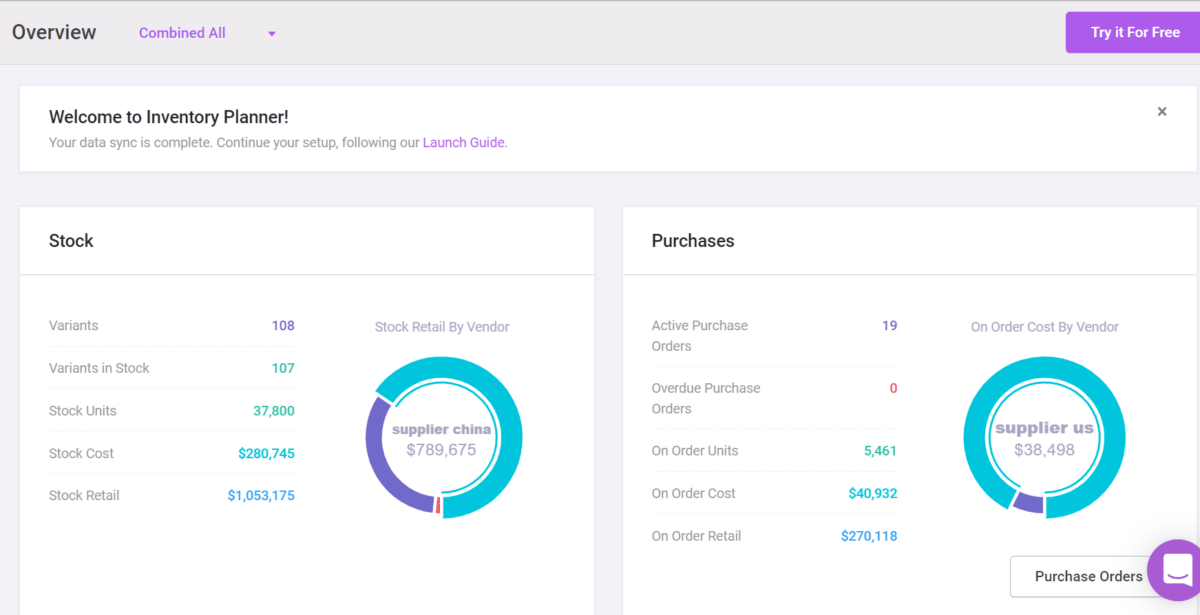

There are inventory management platforms available online. Inventory Planner is a great example and one of the most popular among e-commerce retailers.

A solid demand-forecasting strategy will bring several benefits. For instance, it will allow you to:

- Reduce out-of-stock situations.

- Maintain manageable amounts of inventory.

- Make more logical purchasing decisions.

- Improve budgeting.

- Improve customer-satisfaction rates.

Remember, though, when forecasting demand, you must take other factors into consideration that could affect the results. Some factors to consider are:

Seasons – Certain items only sell at certain points in the year, and your demand forecasting needs to reflect this. For best performance, choose an inventory-planning solution that automatically takes seasonality into account, like Inventory Planner.

Competitors – Have new competitors arrived on the scene? Competition affects demand by giving customers more options. An agile demand-forecasting strategy lets you react quickly to such circumstances to avoid inventory problems.

Types of goods – The types of goods you sell will alter your demand forecasts. For example, some goods may be held longer for repeated monthly subscribers, whereas perishable food items can only be ordered and sold within a certain timeframe.

Always monitor demand forecasts

Setting up demand forecasts is just the start. The key to success lies in monitoring them regularly. The internal and external factors that can affect demand forecasts can appear and change at any moment.

By keeping an eye on your demand forecasts, you’ll be able to account for any upcoming changes and keep your supply chain optimized, which makes demand planning a breeze.

If you’re using a software tool, you’ll want to set up notifications, either daily or weekly, to remind you to check the latest available demand forecasts and other key supply-chain metrics.

Account for demand-forecasting irregularity

Some inventory items have irregular demand. For example, some engineering parts or spare parts for cars aren’t likely to be in constant demand. In fact, many items will have periods of no demand. Items with irregular demand make demand forecasting more difficult. Then there are new products, which can be difficult to make accurate predictions about early on.

With so many variables, it can be hard to keep on top of everything. The best solution for effectively managing your inventory is to use dedicated inventory-planning software. Let’s take a look at how it can help you.

Use a replenishment-planning software

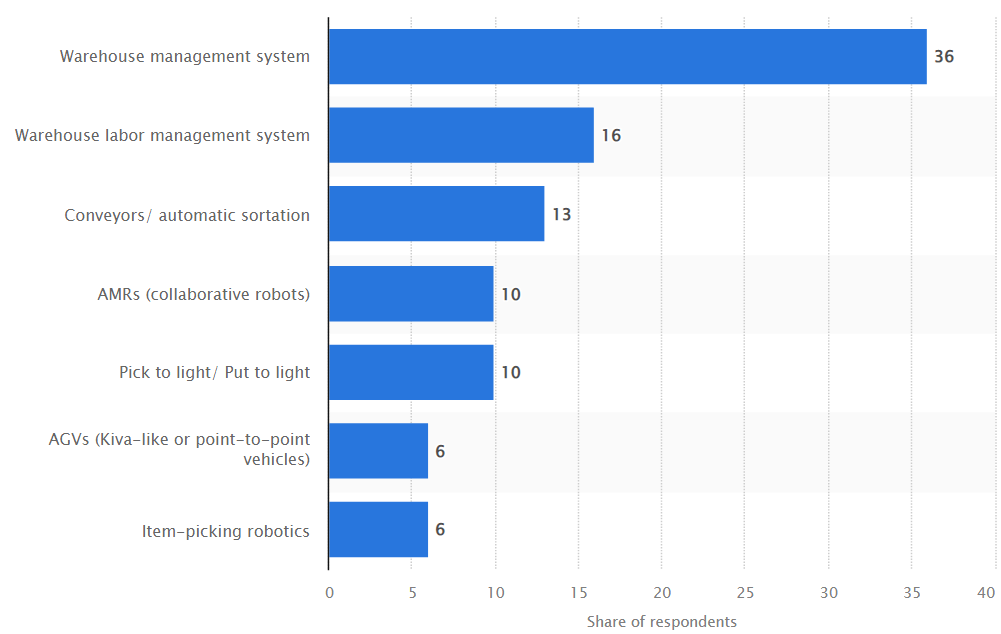

Which of the following warehouse tech investments is the highest priority for your organization? Warehouse management systems come out on top, with 36 of 82 respondents.

These days, manual replenishment planning is only practical for the smallest of businesses with minimal stock turnover. It’s incredibly inefficient for larger businesses and impractical for startups and SMEs that are looking to scale.

Those sorts of businesses need to be aware of the available software that can help and know how to use it properly, especially given that a warehouse management system is the number one priority for warehouses.

Knowing when to order inventory shouldn’t be guesswork. Today’s replenishment-planning tools, such as Inventory Planner, utilize machine learning and AI to enhance and optimize your replenishment-planning strategy. There’s never been a better time to get on board.

Saves money and time

Using replenishment-planning software like Inventory Planner saves money and time.

Why hire extra staff dedicated to replenishment planning and have them work all hours when you can pay a small monthly subscription for software to do the job? And with machine learning, automation, and other clever features, your staff will be free to perform other important duties.

Replenishment for multiple warehouse sites at once will become considerably cheaper with the need for fewer staff members.

More accurate planning

Unfortunately, humans make errors. No matter the experience level of your warehouse staff or managers, emotions, tiredness, and a lack of attention can all lead to catastrophic supply-chain issues.

By letting the software do the work for you, you’ll benefit from more accurate planning that’s backed by data and not by a hunch.

Instantaneous updates

Modern methods of replenishment planning utilize technology and data to provide instantaneous updates. Gone are the days of chasing people up, making countless phone calls, or frantically flicking through pages and pages of spreadsheets.

With the right software, it’s as simple as logging on and viewing the latest updates. Instantaneous updates enable you to take immediate action when things go wrong.

Optimize Replenishment with Inventory Planner

With Inventory Planner, you’ll experience enhanced replenishment planning with next-level accuracy and intuitive insight. That’s why thousands of e-commerce businesses use Inventory Planner for data-driven demand forecasting and replenishment planning.

Inventory Planner saves customers millions in potential lost revenue by helping them work out exactly when and what to reorder to meet demand, even in those more unpredictable times. There’s nothing better for complete warehouse management.

So, if your supply-chain planning needs some optimization with an automatic replenishment-planning tool, look no further than Inventory Planner.

Want to automate your replenishment planning?

See how businesses use Inventory Planner to stay on top of their inventory and cash-flow.

Get a free demo of Inventory Planner

Accurate e-commerce forecasting, even when markets fluctuate.